Minimizing Supply Chain Disruptions

January 2020 is a distant memory, but for most, the early days of the pandemic was a time that will be ingrained in memories for decades, if not generations. Over the last 18 months, supply chain issues have dominated our nightly news, social feeds and family conversations at the dinner table. Some but not all have stemmed from the pandemic.

We have witnessed supply chain disruptions such as the unprecedented demand for toilet paper and cleaning supplies at hoarding levels when people transitioned to work-from-home or schooled-from-home; the global impact of the Suez Canal blockage; to the recent gasoline pipeline ransomware attack causing prices to spike. And now we are seeing a semiconductor chip shortage causing intermittent line shutdowns of the Ford F-150, and near empty show rooms at Toyota dealers. Toyota weathered the early chip shortage well with agile and robust supply chains, only to be caught with final assembly production shortages due to consumers rushing to their once robust availability.

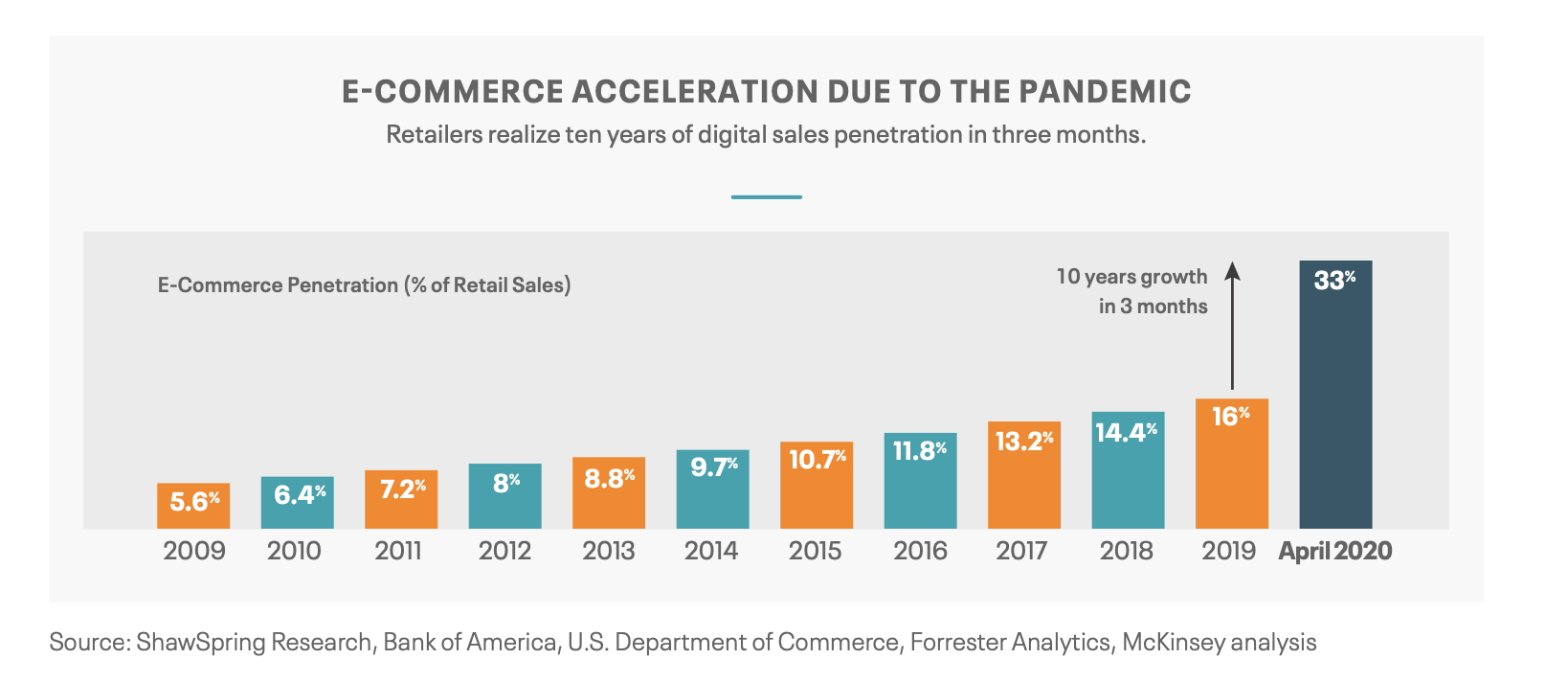

The root cause in part are the changes in the way we interact with others (Zoom connected family members outside of the work environment), work-from-home made people rethink work-life balance (74% of professionals expect remote work to become standard and 97% of employees don’t want to return to the office full-time) and consumers’ shift to e-commerce was revolutionary. Consider that e-commerce’s acceleration due to the pandemic saw retailers’ digital sales penetration realize 10 years of growth in just the first three months of 2020 alone.

In summary, predicting future supply chain demands using last year’s data, just doesn’t work. Accurate demand forecasting can’t rely upon last year’s data based upon dated consumer preferences, lifestyle and demand patterns that just don’t exist today – the world has changed.

Research from the McKinsey Global Institute (MGI) finds that over the course of a decade, the average company can expect to lose nearly half of one year’s profits from supply chain disruptions.

Advanced analytics empower risk reduction

Advanced analytics and enterprise data are empowering several overarching initiatives in supply chain risk reduction – improved visibility and transparency into all aspects of the supply chain balanced with data governance and security.

Improve Visibility within Supply Chains

Advanced analytics and enterprise data empower companies to not only have a completely transparent view of movement of materials and products within their line of sight, but also leverage data from their suppliers to have a holistic view 2-3 tiers deep in the supply chain.

Big data enables predictive analytics to transform demand planning into demand forecasting by analyzing data from tens to hundreds of data sources considering both internal sources (ERP, SCM or MES systems) but also from external sources (market trends, weather, public holidays, consumer pricing indexes, etc.) providing real-time insights into inventory, replenishment and ultimately a distribution plan addressing customer demand.

This capability is leading companies to rethink just-in-time practices. The classical approach to just-in-time delivery, delivering raw material or product at the moment of need with zero inventory, is outdated. The last eighteen months is causing supply chain forecasters to rethink the definition and incorporate risk into the planning process.

Risk modeling was once a qualitative guess, now modeling can leverage enterprise data to deliver quantitative assessments from a larger and more diverse data set. Demand assessments, once singular insights driven by singular events, can now be presented as probabilities predicting a number of scenarios that can offer a range of solutions through targeted discussions, including upside potential and downside risks in sales and operations planning. Advanced predictive analytics and modeling are now optimizing safety stocks and supply chains to include the element in risk so that optimized inventory levels and redundant capital deployment in high risk manufacturing processes are optimized.

Digital Transformation is not without Risk

Those on their digital transformation journey are very aware of additional risk factors when optimizing their supply chain. Enterprise data from external sources (IoT devices, video feeds, beacon and location devices at the edge) provide overwhelming insight, but it is recognized the data from the edge is not risk free. Companies are actively aware that electronic exchange stemming from remote work, ransomware attacks and sensor devices can lead to data corruption caused by shared supply chain data.

Companies are turning to these best practices to reduce supply chain risk:

- Leveraging data where it lies. In recent years the Cloud has been seen as a solution and panacea for many companies digital transformation strategies. However a recent Andereessen Horowitz study has shown that while the Cloud is a viable solution for start-up, expanding and emerging use cases, its true cost on market capitalization is vastly underestimated. Hybrid cloud enables you to unleash the full capabilities of on-premises apps by bursting to the public cloud in order to leverage on-demand infrastructure for highly computational workloads. Choosing enterprise data partners that can deliver hybrid workload solutions reduces risk by leveraging data where it lies, mitigating data transfer risk, minimizing possible confusing redundant data, and optimizing architecture use and spend.

- Open source solutions reduce risk. Point solutions promote themselves as being specialists in specific business process areas and the preferred solution – data warehousing, machine learning as examples. Open source enterprise data solutions are alternative to this risk as they rely upon the power of an external open source community to develop best practice solutions. Cloudera provides the best possible solution powered by the Apache open source community in all its enterprise data experiences in an open architecture, open source software, open APIs, and an open storage format. Open source technologies enable extensibility, flexibility, and avoidance of vendor lock-in, regardless of where the data is stored and workloads are run. This is one of the most important factors of a hybrid cloud because it enables novel solutions in the following ways:

- Access to innovation: The open source community drives change, innovation, and feature functionality at a higher rate than any one organization, even with heavy R&D investment.

- Community of expertise: Mature and active open source communities ensure that your developers are self-sufficient and productive with easy access to expertise and examples.

- Flexibility and choice: Organizations always have access to their data, and don’t get locked-in by any vendor. Open source enables interoperability because the same services that run in private cloud are run in public cloud, so companies aren’t beholden to any one cloud provider’s business model and priorities.

- Keep data lineage secure and governed. An organization, its partner, and customers, all benefit from enterprise-wide multi-function analytics only if data is protected, secured, and governed throughout. Analytics and machine learning can become a risk if data security, governance, lineage, metadata management, and automation is not holistically applied across the entire data lifecycle and all environments. If data access policies and lineage aren’t consistent across an organization’s private cloud and public clouds, gaps will exist in audit logs. This is an InfoSec compliance nightmare because each gap is a potential lawsuit and/or regulatory fine, not to mention the damage to the brand of the company. Gaps also lead to inconsistent insight and, with that, decisions that impact the business’ ability to innovate and differentiate. A hybrid cloud has unified metadata, data access, governance, and lineage across all environments through one common user interface, regardless of where the data is sourced, migrated, or replicated.

In summary, Cloudera is working with companies of all sizes to address and reduce supply chain risk by empowering those companies to use enterprise, edge and third party data for demand forecasting delivering hybrid architecture solutions so that data can be used where it most makes sense, optimizes data infrastructure spend and delivers data governance and lineage.

Read more about my point of view on digital transformation in manufacturing, retail and communications, media & entertainment at cloudera.com/author/david-legrand